Engineered for superior structural integrity and efficiency, the 2W Deck, a composite steel deck, surpasses traditional flooring systems. Explore its technical aspects:

Mechanical Interlock: The 2W Deck features a robust mechanical interlocking mechanism achieved through precision "rolled in" embossments. This design ensures a strong connection with concrete, establishing composite slab action for exceptional stability and strength.

Versatile Functions:

Working Platform: The 2W Deck serves as a stable working platform during construction, ensuring safety for workers.

Concrete Form: Functioning as a concrete form for slabs, it streamlines construction without compromising structural integrity.

Positive Bending Reinforcement: Beyond traditional flooring, it actively reinforces positive bending for a resilient structure.

Resistance to Horizontal Loads: Mechanical interlock and chemical bond resist horizontal shear forces, providing steadfast resistance against various loads.

Fire-Rated Component: As a key component in fire-rated floor assemblies, the 2W Deck ensures safety and regulatory compliance.

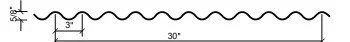

Specifications:

With a 36" coverage, it efficiently covers expansive floor areas.

UL Approved for rigorous safety standards, providing peace of mind.

Galvanized for enhanced corrosion resistance, ensuring longevity.

18GA thickness adds structural robustness.

Available in 12', 20', 24', and 32' lengths for project flexibility.

The 2W Deck blends strength, versatility, and efficiency. Whether as a working platform or a vital part of fire-rated assemblies, it epitomizes the evolution of construction. Elevate your projects with the 2W Deck – where cutting-edge design meets unwavering performance.